Raffaele, please tell us a little about yourselves and your team.

I’m Raffaele Nacchiero, I’m 24 years old and I am a poet who has decided to venture into business, as I like to define myself. I am a management engineer and currently also a PhD student at the Polytechnic University of Bari, where I do research on topics such as supply chain management and circular economy. I am the CEO of AraBat, an innovative startup from Foggia that I founded in February 2022 together with my team, made up of very young professionals and close friends: Vincenzo Scarano (Chief Marketing Officer, CMO), economist with a passion for marketing and digital communication; Leonardo Renna (Chief Financial Officer, CFO), economist who loves art and pure finance; Giovanni Miccolis (Chief Technology Officer, CTO), management engineer with expertise in operations and industrial logistics mechanisms; Leonardo Binetti (Chief Innovation Officer, CInO), materials engineer with a PhD in Engineering and Built Environment from Edinburgh Napier University, a brain drain who returns to Italy thanks to o

ur startup. In addition to being complete and heterogeneous in terms of skills, I am happy to admit that harmony, serenity and inclusive respect for all prevail in our team. Furthermore, I have always been split between technique and art, between engineering and poetry, between a productive and emotional vision of things. In fact, I also studied theater and recently wrote a novel about youth problems. This particular artistic s

ensibility has allowed me to manage many complex dynamics in the administration of the startup with empathy and tolerance.

How was the idea for Arabat born?

The business idea of AraBat was born from an intuition of mine that I had at the end of 2020 in the midst of the pandemic when, leafing through environmental magazines, I realized the global problem of exhausted batteries and the latest innovations in their recycling through biomass. My team and I were engaged at the time in the development of cultural and artistic projects related to the theme of sustainability for our Associazione NemicoRe. The spark immediately struck me: “Why not do even more? Why don’t we create a revolutionary company?

The world needs to recycle end-of-life batteries and here in Apulia we are full of biological waste like orange peels, we could start from here”. The other guys accepted, and we immediately started working together to build our orange dream: recycling spent lithium-ion batteries through a revolutionary technology that exploits organic acids and biological waste. I believe a lot in fate and therefore I believe that every single action we have perpetrated has its own subtle meaning. Becoming today one of the most successful and promising startups in all of Italy in less than a year did not happen by chance, perhaps I had partly foreseen it. Determination, ambition, audacity, megalomania were the right ingredients for our journey. For this fatalistic reason, journalists and friends define AraBat as “the Apulian Miracle” and me as “The Young Seer of Business” and I must say I don’t mind. Despite being very young, I have always aspired to change the status quo and I am trying to do so.

Who has supported you so far?

I can say that AraBat did not immediately have support from institutions or other organizations and that we had to fight for a while relying on our strengths andthose of some other partners. Thanks to the direct channels of Gruppo A.FO.RI.S. and Associazione NemicoRe, in 2021 and therefore before officially establ

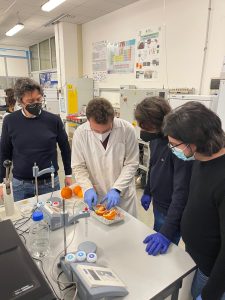

ishing the startup, we told our visionary technological intuition to professor Matteo Francavilla, coordinator of the STAR Facility Centre of the University of Foggia, an industrial biomass valorization centre. Francavilla is a courageous and wonderful person an

d immediately agreed to support us by making the laboratory and his technical skills available to validate our technology which today we have already optimized with extraordinary performance and which we are patenting. Also in 2021, we applied and took part in ARTI Puglia’s “Estrazione dei Talenti” entrepreneurial incubation path which allowed us to strengthen our knowledge and skills in terms of business development and entrepreneurial dynamics.

What does Arabat need now to start its operations?

As of today we have validated our innovative green hydrometallurgy technology to sustainably recycle lithium batteries (which is called “AraMet”) and raised capital through winning several national and international awards such as “ApulianSustainable Innovation Award 2022”, “Digithon (Gino di Pace Award) 2022”, “Smart Agrifood Summit Malaga 2022”, “ENI Award 2022” conferred by the President of the Italian Republic, Sergio Mattarella, at the Quirinale and “Premio Nazionale dell’Innovazi

one 2022 (Cleantech & Energy)”. We have also won and completed an incubation course with the Puglia Region (Estrazione dei Talenti), a pre-acceleration program with Bocconi University of Milan (B4i) and we have recently started an acceleration course with PoliHub (Encubator). We are also closing our first round of investment with a satisfactory valuation of the startup and we are already oriented towards closing a second potential round since towards the second half of the year. The goal is to enter the market as soon as we are ready through an industrial plant (in Apulia, south Italy) or a possible well-structured licensing model. To achieve these objectives, significant capital is needed which we aim to attract gradually.

Can you explain the recycling process of lithium-ion batteries?

Our patent pending AraMet technology consists of a green hydrometallurgy process that allows the sustainable recycling of used lithium batteries (from smartphones, computers and electric vehicles and more) and the recovery of the critical raw materials present inside them. This process can be divided into three major phases: discharge and shredding of spent batteries for the production of black matter; chemical treatment of green leaching through organic acids and biological waste (such as orange peels deriving from agri-food waste); selective precipitation of precious metals which correspond to our final products which we intend to sell on the market.

What metals can be recovered from exhausted batteries using this process?

The main secondary raw materials that we recover from lithium-ion batteries (LIBs) and aim to sell are: nickel hydroxide, cobalt hydroxide, manganese hydroxide, lithium carbonate. Through market research, we have understood the actual need for a circular solution that avoids unsustainable mining and that provides a constant new flow of raw materials in order to protect local companies and national economies from terrible supply chain disruptions and macroeconomic threats, such as the Russia-Ukraine war.

According to analysts at Yole Développement, approximately 705,000 tonnes of end-of-life LIBs are expected to be available by 2025.

This figure is expected to reach 9 million tonnes annually by 2040.

Currently, only a small fraction of LIBs is recycled, and the rest unfortunately goes to landfill.

The total LIBs recycling market was approximately 93,800 tonnes in 2019, which will grow to 459,369 tonnes by 2025 with a CAGR between 2019 and 2025 of 30%.

The value of raw materials present in LIBs destined for recycling is approximately 315 million dollars, which will reach 1,137 million dollars by 2025 and 23,812 million dollars by 2040.

What is the potential environmental impact of conventional recycling processes (pyrometallurgy and conventional hydrometallurgy) and how does AraBat aim to tackle these issues with its green hydrometallurgical solution?

The current lithium battery recycling and metal extraction processes involve the application of a pyrometallurgical method, consisting in the grinding of the batteries, then removal of the iron by magnetic means and treatment in furnaces at temperatures between 700 and  1200 °C. Here mercury, cadmium and zinc are recovered from the fumes, and the residue is mostly composed of iron-manganese alloys or sometimes very impure manganese oxides. As an alternative to this expensive and polluting process, the hydrometallurgical process was developed years ago. The minerals are passed in water on copper plates amalgamated with mercury and chemical reagents such as nitric or sulfuric acid are used at much lower temperatures than the traditional pyrometallurgical process, thus reducing the formation of dioxins, the main cause of pollution.

1200 °C. Here mercury, cadmium and zinc are recovered from the fumes, and the residue is mostly composed of iron-manganese alloys or sometimes very impure manganese oxides. As an alternative to this expensive and polluting process, the hydrometallurgical process was developed years ago. The minerals are passed in water on copper plates amalgamated with mercury and chemical reagents such as nitric or sulfuric acid are used at much lower temperatures than the traditional pyrometallurgical process, thus reducing the formation of dioxins, the main cause of pollution.

However, this conventional hydrometallurgy process also has non-negligible limitations, since it requires the use of chemical reagents and strong acids that are difficult to manage and still high temperatures. AraBat’s green hydrometallurgy is a consistent innovation of the conventional hydrometallurgical process which involves the unprecedented use of leaching support systems, the synergistic use of weak organic acids (such as citric acid) and biological waste (such as orange peels) and a method of capturing CO2 in the precipitation phase. We are able to obtain high performances (e.g. actual leaching efficiency over 80% using rough crushed batteries or purity rate of metals recovered over 90%) with numerous advantages in terms of lower environmental impact and economic savings.

Our process then not only aims to solve the problem of batteries and raw materials, but also that of biological waste, such as the agri-food one, aiming at their relocation and reuse from a circular economy perspective. In Italy, still today, no industrial operator is active in the recycling of lithium batteries and those collected by consortia are shipped to unsustainable industrial plants in Poland, Germany, Belgium and other northern European countries. There are projects under development in Italy, but none already active. We can be the adequate and future solution to this national and continental problem.

What is the global impact of electronic waste according to the Global E-waste Monitor 2020?

According to the United Nations Global E-Waste Monitor 2020, the amount of waste electrical and electronic equipment (WEEE), thrown in the trash, is now growing three times faster than the world’s population. The figures relating to our Puglia region are not reassuring, which counts, in 2019 alone, a quantity of WEEE equal to 8,300,036 kg, of which 2,621,248 kg relating to WEEE containing dangerous substances (such as lithium which can cause fires in plants of treatment). Today we need to focus everything on innovation to constantly identify new ideas and processes to manage hazardous waste such as WEEE and spent batteries which can be transformed into strategic resources for the industrial fabric of the countries through the so-called urban mining.

The European Union, Italy and more generally the institutions must be able to pragmatically support investment programs on projects with a high innovation value through simplified forms of access to public investments and subsidized finance. It is not possible that young startups can be asked to participate in these public instruments if they then have to find the necessary money right from the start to repay the credit received or part of it. We need more risk and more trust in young people who must have the freedom to create without fear and also to make mistakes.

Have you already thought about an international launch of SF? Are you open to collaborations with foreign partners?

AraBat is always open to new potential partners and investors. Our goal is to grow financially to be able to handle the complex challenge of industrialization. It won’t be easy, but I can guarantee that our team has the right perspective to lead this journey, perhaps even together with those who want to risk with us to change the world. Our vision is international, and we aim to expand our network beyond national borders, as we are already doing with a Canadian company or with an international mobility program to be carried out in France for which we have been selected for example.

What are your next steps?

The next steps concern the rapid closure of the investment round I mentioned and the implementation of pilot plant tests to validate the technology on a pre-industrial scale with the support of our partners. At the same time, we will continue our path of innovation, aiming to optimize current technologies and develop new ones. From the soil, the electric revolution: we have given a biological dimension to the electric transition, realizing how a simple orange can change the fate of the world.

But this is not enough for us and we will aim to do even more. Every day I receive emails from journalists, scientists and people we don’t know who compliment us and support us in our crazy entrepreneurial project and we are delighted with this. I hope that the institutions will also be ready when it is necessary to support our planning based on the principles of sustainable development and the circular economy, drivers of the future of humanity.